Implementation of Deep Edge Solutions

We covered the overview of edge computing technology in the whitepaper 'Edge Computing in Industrial Environment'. In this blog, we will discuss more on the Forms of edge computing and implementation of smart edge solutions in an industrial environment.

Implementing effective industrial edge computing solutions necessitates the integration of several components. Core hardware and software applications, physical and cyber security, remote monitoring and maintenance solutions come together to ensure everything stays up and running continuously. In the aforementioned whitepaper section 'The forms of Edge Computing technology' we know the edge devices will be formed into specific sublayers (though individual systems will not use all of them).

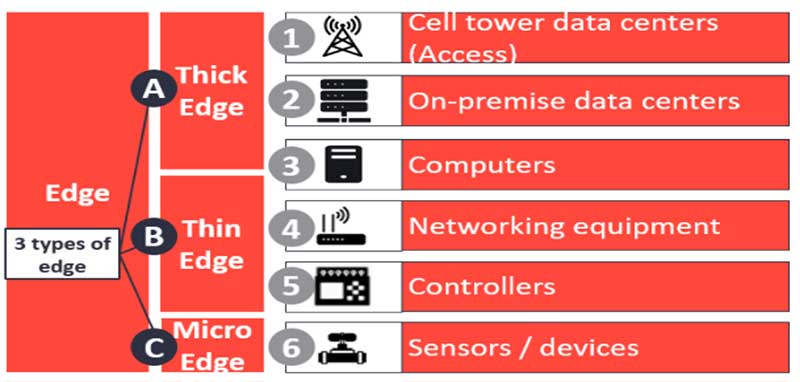

Figure 1: Block Diagram of Thick, Thin and Micro Edge Computing Technology

As shown in above figure the edge computing can be broken down along lines of whether to distribute or centralise the computing in an edge deployment commonly known as the Thick Edge, the Thin Edge and the Micro Edge (collectively known as Deep Edge).

There is a shift to a more distributed and decentralised computing paradigm in Thick Edge computing. Sensors are frequently linked to computing nodes that execute edge applications close to where data is gathered, filtered, aggregated, batched, and so on. The information is subsequently transferred to cloud or business data centre settings. The Thick Edge can also cover computer systems, which have typically been utilised to operate SCADA and similar applications. These local compute nodes (also known as edge devices, edge gateways, or edge computers) are used in Thick Edge computing to offer localised intelligence to act rapidly (with low latency) on data flowing in from physical sensing devices. It performs compute intensive tasks / workloads by adapting high-end CPUs, GPUs, FGPAs, and other processing devices. Thick Edge computing nodes can frequently function independently for long periods of time because of their processing and storage capabilities.

Thin Edge computing involves less processing at the sensor data collecting site. The detected data is gathered and sent to a more centralised processing system, where it is analysed and acted upon. The centralised processing might take place in the cloud or in private data/processing centres (also known as 'on-prem'). It describes the intelligent controllers, networking equipment, PLCs and specialised embedded computers that are built into machine tools and other production equipment. Additional computing platforms (e.g. gateways) may not even be required in Thin Edge compute installations, depending upon the complexity and connection capabilities of the physical sensing equipment. Sometimes it also includes AI components such as GPUs or ASICs.

The Micro Edge represents sensors that collect data from processes and industrial equipment that has typically been directly connected to PLCs or low-end processors owing to cost and power consumption restrictions. It also represents the layer nearest to the shop floor machinery and the part of the industrial computing ecosystem. Since compute resources located at the 'Micro Edge' are the data generating devices themselves.

In fact, there is no distinction between Thin and Thick Edges. At the furthest reaches of the edge, there is more of a ‘spectrum’ of solutions that would tend towards ‘Thin’ or ‘Thick’, based upon resource availability, use case demand, and software deployment and management issues.

Edge Analytics in Industrial environment

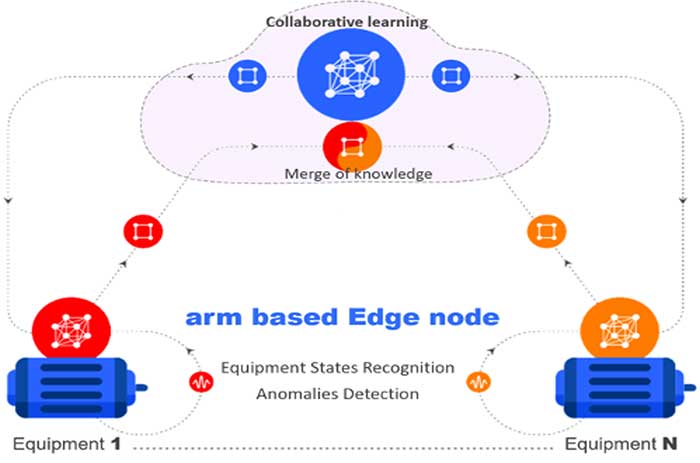

The diagram below shows the concept of having intelligence at the machine's edge and spreading acquired information from one to many machines. Collaborative Learning is the information about a manufacturer's fleet of equipment. The networks allow end users to develop predictive maintenance solutions based upon powerful anomaly detection algorithms, by facilitating information exchange across intelligent edge sensors. The prediction models are trained and tested using the historical labelled data with information about previous failures in the equipment. The amount of historical data can be huge, so real-time storage in the cloud is an effective solution, giving rise to cloud based predictive maintenance. Induction electrical motors are major actuators in most industrial factories, so cloud based predictive maintenance of electric motors is of special importance. Mechanical failures produce vibrations in electrical motors with different amplitude and frequency. Thus, solutions monitoring the health of motors mainly focus on measuring vibrations and temperature. Edge computing resources decouple program from underlying hardware, allowing for flexible architectures in which applications can migrate from one intelligent compute equipment to another equipment.

Figure 2: Industrial Edge node for Anomaly detection

Industrial Edge platform

Industrial Edge is made up of a backend, Edge devices, and Edge apps that are utilised for intelligent data analysis and enhanced productivity. As shown in below figure the components are all part of an integrated hardware and software ecosystem for automation. The Industrial Edge Management System may be used to centrally control and monitor all linked Edge devices. By safely bringing the power of Edge computing and advanced analytics to the production level, Industrial Edge devices deliver machine-level data processing to automation systems.

Figure 3: Industrial Edge Platform

The Application Management is responsible for the deployment, configuration, removal, starting, stopping, and resetting of applications. Users and machine builders can install ‘apps’ on Edge devices and can even design their own applications. Cloud transmission protocols, cloud-based operating systems and Message Queuing Telemetry Transport (MQTT) are all supported by Industrial Edge, making data transfer safe and efficient.

Stay connected with our other inspired blogs where we have discussed about Edge computing deployment strategies and standards, Integration of Edge computing in PACs and PLCs, Edge computing security risks and solutions.

Stay informed

Keep up to date on the latest information and exclusive offers!

Subscribe now

Thanks for subscribing

Well done! You are now part of an elite group who receive the latest info on products, technologies and applications straight to your inbox.