Unlocking seamless industrial connectivity

Introduction

A sophisticated industrial landscape can only be possible with reliable and efficient connectivity. Various systems in an industrial environment can seamlessly connect through industrial connectivity cables and connectors. High-performance cables and connectors are the spine of industrial infrastructure. The exponential increase in demand for higher bandwidth, more excellent reliability, and faster transmission feed new technologies and standards that provide enhanced capabilities but also need careful consideration during selection and implementation. This article covers the present situation of industrial connectivity cables and connectors and their multiple types, highlighting the issues that arise, essential concerns to address, and viable solutions to maintain optimal performance and productivity in industrial settings.

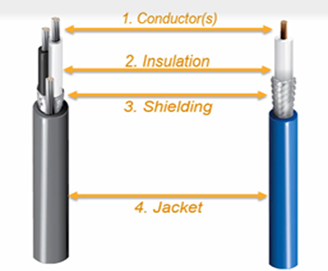

Cable: An assembly of one or more thick, sturdy cords composed of twisted wires. Cables are constructed of a conductor to carry electric current, insulation, shielding, and an outer jacket.

Types of industrial connectivity cables

There are numerous different types of industrial Connectivity Cables on the market, some of which are described below:

A. Ethernet cables

Ethernet cables connect devices in order to transfer broadband data. A LAN (local area network) is a hardwired link between devices. This connection choice is more reliable and has a faster transfer rate than specific alternatives, such as Wi-Fi connections. They are helpful for connecting portable devices such as laptops, printers, and scanners. They can also be hardwired into building structures to enable internet connectivity from one room to the next and throughout the entire building using Ethernet wall connections. They are classified as Cat5e, Cat6, Cat6a, and Cat7, with varying data transmission speeds and bandwidth possibilities. Ethernet cables offer dependable connectivity and are ideal for high-speed data transfer applications.

The following cable types are available:

- UTP - Unshielded twisted pair

- STP - Shielded twisted pair

- U/UTP - Unshielded cable, unshielded twisted pair

- F/UTP - Foil shielded cable, unshielded twisted pair

- U/FTP - Unshielded cable, foil shielded twisted pair

- S/FTP - braided shielded cable, foil shielded twisted pairs

TP stands for twisted pair, U stands for unshielded, F stands for foil shielded, and S stands for braided shield.

B. Fiber optic cables

Fiber optic cables offer excellent performance in terms of bandwidth, data transfer speed, and resilience to electromagnetic interference. These cables carry data using light pulses, making them ideal for long-distance communication and high-bandwidth applications. The core, cladding, and coating are the three essential components of a fiber optic cable.

Core: This is the light transmission area of the fiber, either glass or plastic. The larger the core, the more light that will be transmitted into the fiber.

Cladding: The cladding's job is to provide a lower refractive index at the core interface, causing reflection within the core and allowing light waves to pass through the fiber.

Coating: Coatings are usually multi-layers of plastics applied to preserve fiber strength, absorb shock, and provide extra fiber protection. These buffer coatings are available from 250 microns to 900 microns.

They are two types of fiber optics cable 1) Single-mode 2) Multimode cable

Single mode fiber: A fibre featuring a small light-carrying core of about 9 micrometers (µm) in diameter. The core is surrounded by a cladding that brings the overall diameter of the optical fiber to 125 µm.

Multimode fiber: A fibre with a core of 50 µm or above. A larger core means multiple modes (or rays of light) can travel down the core simultaneously. Just like single mode, the core is surrounded by a cladding that brings the overall diameter of the optical fiber to 125 µm.

C. Coaxial cables

A coaxial cable consists of two conductors (centre and outer conductors) separated by dielectric and overall components covered by an outer jacket. Coaxial cables often convey a radio frequency (RF) signal. The center conductor and outside conductor, or shield, are designed to form concentric cylinders with a common axis (thus coaxial). The characteristic impedance spans from 35 to 185 ohms, with 50 and 75 ohms being common values. Coaxial cables are commonly used for video surveillance and RF signal transfer in industrial settings. Coaxial cables provide ample bandwidth and excellent signal quality, making them ideal for delivering analog and digital communications over long distances.

Coaxial cables are classified into multiple types: flexible cable, semi-rigid cable, triaxial cable, and dual coaxial cable.

Types of industrial connectivity connectors

There are numerous types of industrial connectivity connectors on the market, some of which are described below:

A. Industrial circular ethernet connectors

Circular sealed RJ45 connectors provide high-performance CAT 5E/6A ethernet connections for harsh environments. When employing shielded cabling, only shielded connections should be used. Tailor the connector to the context in which it will be utilised. In most industrial applications, an IP65 or IP67 connector is preferred to prevent pollutants from entering the connector and reducing performance. RJ45 connectors for industrial applications are typically bigger and have a locking mechanism. It incorporates an IP67 sealing gasket system to keep pollutants and vibration out. In clean environments or inside control cabinets, a smaller IP20 version is employed.

Single pair ethernet (SPE) connector: Single pair ethernet will be the next generation of Industrial IOT connectivity architecture. It is possible to use Ethernet at the field level with SPE infrastructure, from the cloud to the sensor-actuator networks. This minimises data processing delays and offers a consistent base for communication, making IIoT conceivable. SPE cables are thinner and more flexible than standard Ethernet cables since they include one pair of wires. The thinner the cable, the better it can handle bending and torsion cycles, resulting in longer service life and lower costs. As a result, SPE is the appropriate cabling for future robotic applications. To learn more about SPE, click here.

B. Fiber optic connectors

Instead of transferring electric signals, this industrial automation connector transmits light. They align microscopic optical fibres in interconnect cables, media converters, or optical switches.

The connector comprises the ferrule, the coupling mechanism, and the connector body. The ferrule is the component that secures the fibreglass to the cable fibre. The connection body is made of metal or plastic to support the ferrule. Finally, the coupling mechanism is highly beneficial in holding the connector in place after it is connected to other peripheral devices.

ST, SC, FC, and LC fibre optic connectors are the most common. ST is a straight tip with a 2.5mm ferrule made of metal or plastic commonly used in fibre optics. The SC-type ferrule is 2.5mm in diameter and is designed to hold a single fibre together. It features a push-on and pull-off mechanism for connecting and disconnecting. The FC-type is useful in the telecommunications business. They have a threaded coupling that provides a strong and long-lasting connection. Finally, the LC type has a well-designed retention tab in a duplex style with a polymer clip.

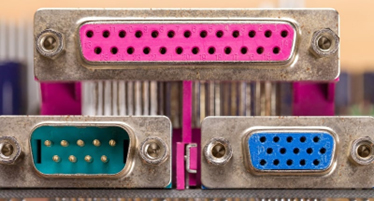

C. D-Subminiature connectors

D-Sub is an abbreviation for D subminiature. This connector has always been used in various fields of industrial automation, particularly computers. They are employed in low-current, low-speed circuits such as micro switches, trim motors, and data signal control and display devices. The type offers male and female D-Sub connectors with pin counts ranging from 9 to 50 and a few standard variations.

Factors to consider when choosing industrial connectivity cables and connectors

Several aspects should be addressed whilst selecting industrial communication cables and connectors. These elements are as follows:

- Environment: Examine the environment in which the cables and connections will be used. Consider temperature extremes, moisture, chemical or pollutant exposure, and physical stress. Choose cables and connectors that are built to resist and operate effectively in the environment.

- Data transmission speed: Determine the data transmission speed required for your application. The bandwidth capacities of various cables and connections differ. Check that the cables and connectors you choose can handle the data speeds as are necessary for efficient communication without bottlenecks.

- Distance: Consider the length of the wires required to convey signals. Certain types of cables, such as fibre optic cables, are more suited for long-distance transmission than others. Check that the cables you choose can retain signal integrity over the desired distance.

- Signal integrity: Determine the signal integrity level required for your application. Electromagnetic interference (EMI) and signal attenuation should be considered. Use cables and connectors with enough shielding and insulation to reduce signal degradation and interference.

- Reliability and durability: Examine the cables' and connections' dependability and durability. Vibrations, collisions, and other stress can occur in industrial situations. Look for industrial cables and connectors that can survive severe environments without affecting performance.

- Compatibility: Check for compatibility between the cables and connections and the equipment or systems with which they will be utilised. Consider the connector types, pin configurations, and requirements needed for seamless integration.

- Current rating: The current rating is the amount of current that the system can safely carry indefinitely. Some connectors can handle larger currents for short periods of time.

- Ingress protection (IP rating): This specifies how well a connector is protected against liquid and solid object entry. A quick glance at the IP reveals two digits: the protection level against solid material and the representation against liquid infiltration.

- Standard approval: Make certain that the connector you choose has been tested to ensure that it meets the appropriate industrial standards set by local government bodies such as the NFPA and UL in North America.

Conclusion

Industrial connectivity cables and connectors ensure reliable and effective communication in industrial settings. Understanding the many types of cables and connections available is essential when selecting the best solution for certain industrial applications, considering elements such as the environment, data transmission speed, distance, and cost. Industries can optimise operations, increase efficiency, and achieve seamless communication in the current industrial landscape by making informed judgments and selecting the proper cables and connectors.

Farnell has partnered with many different suppliers catering to a wide range of cables and connectors components portfolio, such as connectors, cable, wire & cable assemblies, circular connectors & components, d sub connectors & components, RF / coaxial connectors & accessories, coaxial cable, fiber optic cable and rectangular power connectors & components and so on.