The transportation process in the IoT world

Out in the Alaskan wilderness, IoT technologies are ensuring the safe passage of goods and services along one of the harshest stretches of highway in the United States . The Alaska Department of Transportation and Public Services has used Cisco solutions to manage highly secure radio, channel and media resources, co-ordinate dispatching, and provide network connectivity for the roadways. The implementation allows fast response to emergency situations, improved safety, and significantly more efficient equipment management and maintenance.

Fig1. In the Alaskan wilderness, IoT technologies are ensuring the safe passage of goods. Image via Getty

While this is an extreme environment, the IoT is playing an increasingly significant role in transportation systems of all types – rail, sea and air as well as road – around the world. These advances are allowing the transportation industries to keep pace with their manufacturing customers; other articles on the IoT Hub have shown how productivity, competitiveness and granularity of choice in factories and warehouses is being boosted by the evolving sensor, networking and cloud technologies comprising the IoT.

So, if advanced manufacturing needs the support of advanced transportation, how is the transportation industry rising to the challenge? What are the components of a transportation system, how can they be modified by the IoT, and where will the benefits arise? Below, we explore these questions and their answers.

If we focus on road transportation systems, we can be more specific about the challenges and potential benefits – both of which are huge, as last year the US trucking industry generated $676b , compared with Apple, Amazon and Google’s combined revenue of $442b. Issues confronting this large industry include a shortage of drivers, increasing costs of downtime due to breakdown or accidents, theft of vehicles or loads, operational efficiency, and growing demands for real-time information about freight status; not only its geographical location, but also details about exactly which items a shipment contains. Additionally, if the shipment comprises perishable food or pharmaceutical goods, early information about any refrigeration or other environmental control problems is required, so that they can be fixed before valuable and possibly irreplaceable stock is destroyed.

These problems become more complex for large and international shipping operations, as these are fragmented and involve many different carriers, warehouses and vehicles along the route. Accordingly, after looking at the issues named above, we review the challenges of a large or international operation, and a possible IoT-based solution.

Truck driving automation

Some of these issues could be resolved through increased truck driving automation; augmenting drivers or eventually eliminating the need for them entirely. Although the cost of using automation to achieve smart trucking would be high, it would likely be economic compared to drivers’ annual wages. In any case, while the reality of highways populated with self-driving vehicles may be somewhat futuristic, there are already some limited applications. Mining conglomerate Rio Tinto has been operating automated fleets of massive trucks since 2008 in a remote region of Western Australia, reducing loading and hauling costs by roughly 13%. Required breaks, absenteeism, shift change costs and meal logistics are eliminated, while removing people from the mine environment increases safety.

Fig2. Rio Tinto operates automated fleets since 2008. - Image via Getty

Truck convoys provide another opportunity for autonomous driving. The lead truck driver retains control of all steering functions and sets the pace. Drivers in the following trucks provide no steering, acceleration or braking control, and technically may not be needed once the convoy is underway. The system reduces accident rates and can reduce fuel consumption by about 15%. Road space is better utilised, and carbon emissions are cut.

One successfully tested convoy was led by a Volvo truck in Barcelona, Spain. The driver provided steering functions for the four following vehicles. The journey towards full automation will progress through intermediate steps; experimentation is already under way.

Autonomous driving could reduce the number of trucking-related accidents, which can cost hundreds of thousands of dollars per incident, or even millions if a fatality is involved. It could also help with the shortage of truck drivers; The American Trucking Association has estimated that the US faced a 48,000 shortfall in drivers in 2015, growing to possibly 175,000 in 2024.

While increasing automation of the driving function could bring benefits as described, there’s plenty that the IoT can achieve by detecting, gathering, analysing and alerting users to events in vehicles at any level of automation. Increasingly, trucks are fitted with sensors monitoring engine behaviour, driver behaviour, load status and truck location. Many different systems integrators are using data from these sensors, together with cloud-based analytics, to generate actionable information for fleet operators.

Next-generation track and trace

In 2012, FreightWatch recorded 946 cargo theft incidents in America, and 689 in Europe; activities that cost shippers billions of dollars each year in inventory delays as well as stolen goods costs. Blackberry Radar is one system that operators can use to combat this:

- Delivers near real-time on the location of trailers and containers to a portal which can be viewed anywhere, on any smartphone, tablet or computer.

- Based on an asset tracking device that’s easily installed on a trailer.

- Identify where assets are, how they’re being used, identify and prevent opportunities for theft and drains on efficiency

- Detect when truck crosses user-defined geofence or when a trailer door has opened or closed

- Monitors temperature, humidity and cargo presence to check for problems that could threaten cargo integrity

- Notifies warehouse staff of impending arrival so they can plan accordingly

- Security is assured as all transmitted data is encrypted, and all devices and cloud endpoints are authenticated

- No need for costly IT infrastructure as the system is cloud-based

- Other systems can also improve security by monitoring door sensors, establishing reliable two-way communications and panic buttons, and help prevent hijacking by detecting GPS and GSM signal jammer activity. GPS information can also be used to track stolen vehicles.

Similarly, DHL offers a couple of SmartSensor products ; SmartSensor RFID is a UHF RFID passive device that measures temperatures during transportation. Its data can be analysed retrospectively through DHL’s web portal anywhere in the world and at any time. It fulfils pharmaceutical regulations EU GMP Annex 11, US 21 CFR Part 11 and EU GDP.

SmartSensor GSM measures temperature, humidity, shock and light data (door opening), and identifies location during transportation. It uploads its data over the GSM mobile phone network to DHL’s web portal for near real-time data analysis.

Moving from preventive to predictive maintenance

As well as monitoring freight movements and conditions, the IoT is helping fleet operators improve truck uptime by using predictive rather than preventative maintenance. Manufacturer International Truck has launched a program called OnCommand Connection that exploits Big Data and IoT technologies to minimise disruption to truck services. Every IT truck built since Summer 2015 has a telematics option which plugs into the engine and reads data from other components in the truck system.

- Monitors engine speed, truck speed, coolant temperature, brake wear and other variables

- Data collected at 15 to 60 second intervals, and transmitted over cellular networks to (mostly) an Amazon Web Services repository for access by IT and their customers.

- The data is then loaded into a Hadoop cluster for analysis using machine learning algorithms written in Python, R and SAS.

- Analytic results help TI improve their own internal testing mechanisms and engage customers on predictive maintenance activities

- The Hadoup cluster is expected to exceed 1 petabyte of data, supporting over 200,000 trucks.

- Can predict how different truck configurations and part combinations – of which there are about 20,000 possibilities – react with one another in the real world, and generate alerts if these predictions and sensor inputs indicate a latent fault.

- Predictive maintenance reduces downtime, important as each truck day off the road can cost up to $1000 in lost revenue

Looking after the drivers, and ensuring regulatory compliance

Drivers can be considered as components of a truck’s system, just like the engine, brakes and load. As such, they and the operators can equally benefit from monitoring, feedback and recommendations for improvement.

- Dispatchers can remotely monitor real-time fuel efficiency; do drivers brake or accelerate too hard?

- Recommend optimum speed for a route

- Track driver routes, time spent loading and unloading,

- Manage hours of service compliance

- A system can become smarter as it gains feedback, and better able to advise on road conditions, loading docks, weather conditions and any other factors that could impact a delivery schedule

- Electronic Logging Devices (ELDs); The Federal Motor Carrier Safety Administrator (FMCSA), responsible for regulating and providing safety oversight of commercial motor vehicles, mandates that US truck drivers must use an ELD . This collects information related to location, date, time, vehicle and driver ID, engine power status, vehicle motion status, miles driven, and engine operation hours.

- ELDS can be paired with smartphones to store and back up collected information, facilitating organised and systematic data collection.

- Regulatory compliance is assured with accurate hours of service (HOS) and vehicle maintenance data recording

- Drivers have been found to like these devices, as they eliminate hours of time completing paper logbooks to comply with hours of service regulations. ELD evidence can also exonerate drivers in the event of a disputed incident.

- It is also possible to use ELD data to model driver fatigue risk . Predictive modelling technology uses thousands of data points to build a true picture of a driver’s behaviour and present an opportunity for remediation.

Using connected freight technology to provide a reliable and visible global shipping solution

International and other large-scale freight shipping operations can involve transit through many different operators, vehicles and waystations. Plenty of opportunities for error arise if humans in the field fail to behave as expected - for example, putting a parcel into the wrong truck after scanning it. The centralised system no longer has an accurate view of what’s really happening. This is exacerbated as the freight is probably travelling through a complex, fragmented mesh of waypoints or warehouses owned by different service providers along the route.

Traditional track and trace implementations have attempted to improve this scenario with more efficient systems, but IoT technology is now enabling a newer and entirely better approach. Intel , for example, has developed a global system based on making freight smart. This is based on smart sensors attached to each box or item that can feed data back to a central or Cloud resource through mobile gateways on the vehicle, or fixed gateways inside way points.

- Freight stakeholders gain a single, coherent view of freight status as it moves through the system

- Real-time shipping information can be fed to both existing systems and new big data analytics systems, giving customers access to shipping information during transit

- Temperature sensors and accelerometers allow customers to monitor freight conditions, and take corrective action if necessary. This may mean changing the shipping container environment, or re-routing the freight to another destination.

- The data collected can also facilitate longer-term visibility and planning

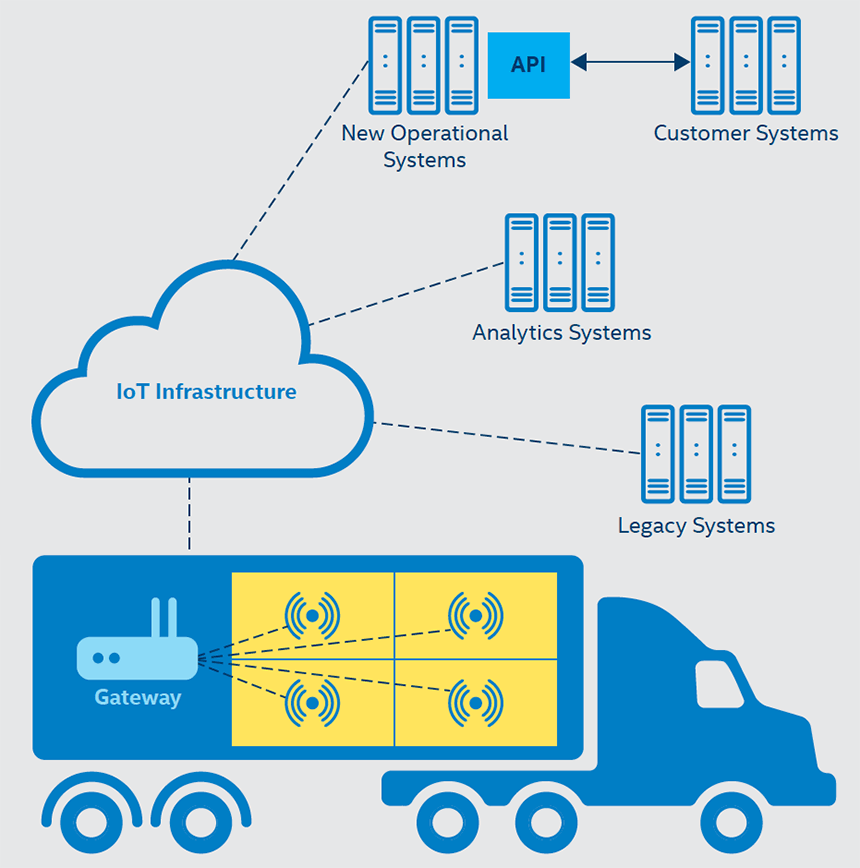

Fig. 3: Intel smart freight system – Image via Intel

The Intel IoT Platform is a reference architecture for connecting freight sensor tracking technology to gateways that communicate with a customer’s legacy data analytics and management system via an API firewall. It comprises the following components:

- Smart sensors: Sensors with integrated processor, memory and wireless communications functions, attached to packages

- Gateways: Mobile, battery-powered devices that accompany transit loads, and fixed waypoint versions associated with packages that have been received and/or are yet to be shipped. Managed by an application specifically designed to accept and provision against shipment parameters, including operating system and applicable packages for security, manageability and local analytics.

- Configurator: Cloud application that interfaces with customer apps to create configuration parameters for each load, including parameter adjustments.

- State reconciliation engine: Cloud application that manages consistency between gateways and abstractions residing in customers’ operational systems – shipments, loads and waypoints.

- Clearinghouse: Cloud application managing communications between gateways and customer applications – legacy, logistics and operational; inbound periodic events and out-of-cycle events that are received here for exchange with customer systems; outbound state changes and method invocations are received by clearinghouse for transmission to gateways.

- Software development kits (SDKs): Tools provided for customers building new operational systems to ensure forward compatibility with gateway, clearinghouse, configurator and state reconciliation engine feature enhancements.

Conclusion

Freight transportation, especially when perishable goods are involved, can be complex and difficult to manage; adverse events can affect drivers, vehicles and freight. In this article we have seen how the IoT’s control and monitoring capabilities can alleviate these issues. A roadmap to automated and even entirely driverless vehicles has been established, and in some implementations, these have already become a reality. The drivers also see benefit from being able to maintain compliance more easily and with less paperwork.

Using IoT networks of low cost, rugged wireless sensors and mobile gateways, tracking freight also becomes easier and more reliable. Sensor-enabled freight items can talk to central control stations; operators can see, in real time, where the freight is and the conditions it is experiencing, rather than relying on indirect, delayed and possibly incorrect information from scanners and manual data entry devices.

The benefits of exploiting IoT technology in this way are numerous. Costs arising from wasted fuel, truck downtime, driver issues and spoiled freight can be avoided, while profits can be improved by diverting freight to alternative destinations if market opportunities present themselves while shipments are en route.

References

http://www.ioti.com/analytics/smart-trucking-ai-s-impact-fleet-management

https://www.ft.com/content/43f7436a-7632-11e5-a95a-27d368e1ddf7

https://ricardo.com/news-and-media/press-releases/sartre-road-train-premieres-on-public-roads

DHL Trend Report, ‘Internet of Things’

http://www.dhl.com/en/about_us/logistics_insights/dhl_trend_research/smartsensor.html

https://www.datanami.com/2015/10/14/trucking-along-with-big-data-and-the-iot

https://insights.samsung.com/2015/12/17/iot-logistics-are-transforming-the-trucking-industry

http://eldcentral.com/the-10-basics-to-understanding-eld-compliance

http://www.omnitracs.com/products/fatigue-model

The transportation process in the IoT world. Date published: 1st November 2017 by Farnell element14