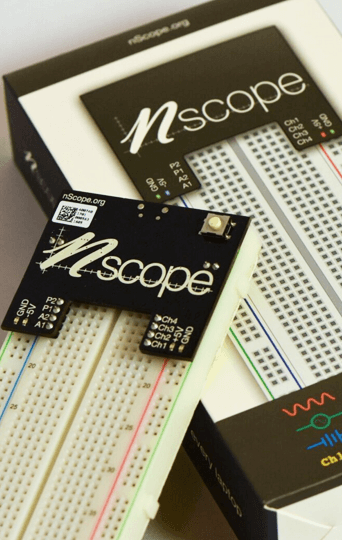

nScope: The portable electronics lab for creative learning on the go

nScope is a portable electronics lab that was conceived as a platform to facilitate hands-on electronics training to engineering students.

After raising over $180,000 from backers on Kickstarter, creators Nick Marchuk and David Meyer teamed up with Premier Farnell and our subsidiary company MCM for manufacturing, packaging and distribution. We spoke to them about the process of developing the nScope and the secrets behind a successful crowd funding campaign...

In a nutshell, what is nScope?

David: nScope is a USB Oscilloscope, power supply and function generator. We developed it as a learning tool for schools that want to offer a more hands-on experience with electronics, or for people without access to a traditional lab environment.

How did the project come about?

Nick: David and I were both working as Teaching Assistants at Northwestern University. When it came to introducing circuits, we struggled to find the right equipment to ensure that every student got a hands-on experience.

Working in the lab, we would traditionally seat four pupils at each bench, but this would usually result in one pupil doing all the work while the other three watched. We decided that making our own hardware rather than buying it from elsewhere might provide more value.

We built the first nScope in 2010, and every summer we’d revisit it and create a new version that addressed any problems we’d encountered with the previous iteration. In 2013 we decided to finalise the hardware, which led to our Kickstarter campaign. After that, the project really took off.

What was your path to a career in Electronics and Engineering?

Nick: I grew up on a farm in New Jersey, so I had a lot of hands-on experience of building things through that. I also had a physics teacher at school who really turned me on to robotics, which I subsequently decided to study at college. I got my degree in Mechanical Engineering, and then came to Northwestern to work on Human-Computer Interaction Robotics. Working as a Teaching Assistant meant that I really had to learn more about electronics so that I could teach it effectively.

David: My parents both have backgrounds in electrical engineering, but I actually hated electronics as a kid, despite their best efforts to get me interested in it. What I really wanted to do was build rollercoasters, so I went to school for mechanical engineering. It wasn’t until I came to Northwestern to pursue my Graduate studies that I realised that if I wanted to build really cool stuff, electronics was something I’d need to dive into.

Like Nick, I picked a lot up from working as a Teaching Assistant in electronics classes. It was a steep learning curve, but pretty fun, and it helped me to understand what a valuable tool it is being able to build something right on your desk. It inspired me.

Obviously crowd funding has played a major role in the nScope project. What made you decide to go down that route?

David: We briefly featured the nScope in a video we produced for our electronics class. The video went a little viral, and we got a lot of comments from people asking what the nScope was. This gave us the idea that it might be something other people might want to use.

We chose Kickstarter not only as a way of securing funding for build and production, but also to get the word out. We knew that there was potential to reach a much larger audience than we’d be able to attract by ourselves.

So many crowd funding initiatives fail at the first hurdle – why do you think yours was so successful?

Nick: We’ve been asked this question so many times, and to be perfectly honest, we don’t really know! My best guess is that we spent time really thinking about the story we were trying to tell. We didn’t hire anybody to do marketing for us, we shot the videos on our own cameras and we edited them on our own computers

David: I think we had an advantage in that we’d been working on the nScope for about five years before we launched the Kickstarter. I think it came across in our video that we were genuinely interested and invested in the project. Also, we’d already proved that the device worked ‘in situ’, so there was very little risk for a potential backer in terms of whether it would succeed or not. Ultimately, I think people just felt confident that we knew what we were doing.

You both developed the nScope while working and studying at Northwestern University. To what extent did that help to shape the project?

Nick: Northwestern has always provided a great deal of support in terms of providing feedback and access to the basic resources that we needed to develop the nScope. Without that infrastructure, it would have been very difficult to set up a project like this.

David: Because we developed the nScope at Northwestern, it was technically their property. When we told them about the project, they gave us the rights to go away and do whatever we wanted with it. Given how much we relied on their facilities during the build, that was incredibly generous of them.

What are some of the most rewarding aspects of working on nScope?

Nick: I think it’s most exciting to see students come in without any experience with electronics and to watch them really gain confidence over the course of a few weeks.

Teaching electronics on a chalkboard isn’t as much fun for the student or the teacher. There’s less opportunity to experience the actual physics of the system. Once they start trying things out for themselves, you can really see the connections they make between concepts that they’ve learned and the real-world applications they’re recreating at the table.

I’ve also seen a few quite exciting projects in which people are using nScope for things like audio filtering and tuning ultrasonic range finders. That tells me that the device has utility beyond just teaching.

How did Premier Farnell and our subsidiary companies such as MCM become involved with nScope?

Nick: The interesting thing about running a Kickstarter campaign is that as soon as you get funded, a lot of people start contacting you with offers to help with aspects like manufacture, production and retail. It can be quite difficult to gauge who you can trust and who’s just trying to scam you.

At the same time, we did need support on all of those things. When Newark element14 got in touch, we were attracted by the fact that we already knew that they were the real deal, and that they had an excellent record for manufacturing.

Also, they had an office in Chicago, which was really helpful to us because we could meet people face to face and develop a working relationship that allowed us to get a clearer view of things like costs, packaging and manufacture throughout the process.

As engineers, we’ve never manufactured anything at this scale before, so having a company like Newark element14 approach us with a really reasonable quote, and prove to be so easy to work with, has really helped us to fulfil our Kickstarter orders and move the project forwards.

What are some of the biggest challenges you’ve encountered so far in developing nScope?

David: Neither of us are software engineers, so one thing we’ve had to learn quite quickly is how to develop practices for delivering the software that we have. We’re still not quite where we’d like to be in that respect, so we’re continuing to iterate on that.

Another challenge could be summed up as ‘everything that isn’t engineering’. Going into this, we came up against a lot of things that we’d never really had to think about before – from sourcing parts to working with international customs – all the fundamentals of running a business, essentially.

To give an example, we had to ship 2,300 units to our Kickstarter backers by hand. We’d make a box, package the units, print out labels and physically ship them out. If you can’t afford to pay somebody to do that for you, it can mean a lot of late nights!

Tell us about the hardware that you use in the nScope...

David: The backbone of the nScope is a Microchip PIC24FJ microcontroller, which we use primarily because it’s the microcontroller that all of the courses here at Northwestern are taught with, so we’re very familiar with it. It also runs a USB stack that I was able to work with to alleviate the problems of driver availability on the computers, which was another reason to use it.

We also have several analog chips that use signal conditioning to feed into the converters on board the PIC Microchip, plus a power circuit that protects the power supply on the breadboard against shorts, overcurrent, overvoltage etc. We use chips from Microchip, Texas Instruments, Linear Technology and more – we really shop around to find the right chips to deliver the features we need.

Where do you see nScope 12 months from now?

Nick: Our plan is to develop an online curriculum with freely available tutorials and videos that are centred around, but not dependent on, the nScope equipment. Whether it’s students, people looking to get back into electronics after learning about it at school or those who are interested in picking up a new hobby, we don’t want to prevent anyone from learning who wants to.

What about three to five years from now?

Nick: We have two directions that we’re looking at. One is the hobbyist community – making nScope a tool that you’d use with devices like the Arduino and the Raspberry Pi.

The other is going even further into the education community. We already have several Universities running Pi programs as an introduction to electronics. In the next few years we hope to have schools and Universities adopting nScope in their classes as well. We’d also like to run some kind of MOOC, so that students who don’t have access to traditional electronics facilities can follow along.

Aside from nScope, what other start-ups or emerging technologies are you excited about at the moment?

David: I’m part of a start-up called Tanvas, where we’re developing haptic touchscreen technology. That’s currently consuming about 80% of my working life!

Another thing I’m really interested in right now is virtual and augmented reality. In the next few years I think we’re going to see a real explosion in VR tools. It’s going to be like when the Smartphone first came out, it’s going to change a lot of things.

What advice would you give to other start-ups in the engineering space that are looking for opportunities to develop their projects and take them onto the market?

Nick: We were recently part of the National Science Foundation’s I-Corps program, which helped us to develop nScope as an engineering educational tool. One thing they taught us was the importance of customer discovery. That’s something we did quite naively at Northwestern, because we had five years to talk to our students and figure out what they needed. It’s an incredibly important process – if you come up with a cool thing but don’t think about who’s using it, who’s paying for it and what they actually want from it, your product is never going to go anywhere.

Another important consideration is cracking your message. When you’re running a project on a platform like Kickstarter, you’re not so much selling a product as an idea. If people don’t buy into that idea, your project is likely to fail. Take the time to really craft your central message in a clear and concise way. It took us a very long time to iterate down to the final video that we used in our Kickstarter campaign, but I think it paid off.

Finally, don’t be too ambitious. There are certain features that are commonly found on full-price oscilloscopes that we consciously decided not to implement on the nScope, because they would have increased the cost and complexity, and some of the key benefits of the unit are that it’s simple and inexpensive. Our goal was to identify what we wanted to do, and to focus on doing it really well. That felt like a good decision.

For more information about Premier Farnell’s partnership with nScope, read our case study on the element14 community.