How to optimize low-power operation for sensor applications

Low-power sensing refers to techniques and technologies that reduce sensors' energy consumption while maintaining or enhancing their functionality.

This is essential for applications where sensors are used in environments with limited power access, such as wearable devices, remote monitoring systems, and Internet of Things (IoT) applications. This article discusses the factors to consider when reducing a sensor's power demand.

Factors to consider for power optimization in sensors

Choose the right sensor for your application:

Selecting sensors that match your application's needs is crucial for reducing power consumption. Different sensors have varying power demands. For instance, a camera sensor consumes more power than a temperature sensor, and higher resolutions increase power usage. Opt for sensors with technologies like Micro-Electrical Systems (MEMS), which inherently consume less power.

Duty cycling and sleep modes:

Implementing low-power design principles is essential for optimizing energy consumption and extending battery life. One effective technique is duty cycling, which allows the sensor to periodically enter a low-power sleep mode, significantly reducing power usage. Integrating low-power components, efficient signal processing algorithms, and robust power management systems is crucial for maintaining high performance while minimizing energy consumption.

Adaptive sampling rates and dynamic power scaling optimize power usage by adjusting based on real-time operational demands and environmental conditions. The sensor operates only when necessary and at the lowest effective power level to conserve energy and extend the system's operational lifespan.

Reducing sensor sampling rate:

Lowering the sampling rate of a sensor significantly decreases power consumption by shortening its active time and operational frequency. This diminishes the need for data handling, transmission, and processing, allowing sensors and peripherals to enter low-power sleep modes more frequently. Consequently, power demands on the supply are reduced, minimizing heat dissipation, and improving battery efficiency. This approach extends battery life, enhances the power budget, and enables better integration of other features without compromising system performance. Lowering the sampling rate is highly effective in applications where continuous high-frequency sampling is unnecessary.

Figure 1: Low-power sensor modes for design efficiency (Source)

The most direct method for achieving low power consumption in sensor design is incorporating lower power states such as shutdown and low-power operating modes. This allows system designers to directly control the sensor’s operation directly, offering significant power savings, as shown in Figure 1.

Efficient data processing techniques

a) On-sensor data processing: This reduces power consumption by minimizing data transmission, decreasing the load on central processors, enabling more effective power management, and reducing the need for high-power infrastructure. On-Sensor data processing leads to significant energy savings and improved system efficiency, especially in battery-powered and remote applications.

b) Integrating an MCU with the sensor: Integrating an MCU with sensors allows for local computation, reducing power consumption by offloading tasks from the main processor. This approach enables complex computations directly on the MCU, which consumes significantly less power than the main system processor. For example, in a fitness tracker, continuous monitoring can strain a smartphone's battery, but using a dedicated MCU for local processing ensures efficient operation without draining the main device. This strategy preserves battery life by keeping the primary processor and other components in low-power states when not actively processing sensor data. Integrating sensor functions with an MCU optimizes energy usage, making applications more sustainable and extending device battery life.

Reducing sensor power consumption through power-efficient communication

Reducing sensor power consumption through power-efficient communication is vital for extending the operational lifespan of devices. Significant energy savings can be achieved by optimizing data transmission methods and employing low-power communication protocols.

- Minimized Data Transmission: Techniques like data compression and aggregation reduce the data volume, decreasing the power needed for communication.

- Lower Transmission Frequency: Event-driven and scheduled transmissions limit the frequency of data sent, saving energy by keeping sensors in low-power states longer.

- Efficient Communication Protocols: Low-power protocols such as Zigbee and BLE and adaptive protocols that adjust transmission parameters reduce energy usage.

- Optimized Radio Usage: Shorter transmission times and low-power radio modes reduce active periods and power consumption.

- Energy-Efficient Hardware: Low-power transceivers and energy harvesting further reduce power needs.

- Improved Network Efficiency: Efficient network topologies and smart routing reduce transmission power and frequency.

- Reduced Overhead: Streamlined protocols and optimized payload sizes minimize unnecessary data transmissions, saving energy.

- Lower Signal Strength: Adaptive signal power and proximity-based communication ensure efficient energy use for data transfer.

Minimize leakage currents

Minimizing current leakage in sensor design is essential for enhancing energy efficiency and extending battery life. This can be achieved by:

- Using low-leakage components, such as specialized CMOS technologies and precision resistors.

- Optimizing circuit design to reduce node capacitance and isolate high-impedance nodes.

- Selecting low-leakage transistors and employing advanced techniques like body biasing in integrated circuits.

- Implement proper PCB design and use high-quality materials with adequate grounding and shielding techniques.

- Utilizing low-leakage power supplies and optimizing sensor interfaces.

- Applying advanced leakage reduction methods like reverse biasing and adaptive control.

- Regular testing and validation ensure these strategies are effectively implemented across varying environmental conditions.

Implement Power Gating Switches

Power Gating Transistors (usually PMOS or NMOS) can be used as switches to disconnect the power supply to specific blocks when idle. Design control signals to activate or deactivate these switches based on the sensor's operational state.

Software optimization

Optimize code, use predictive power management, and enable context-aware operation to tailor sensor activity and minimize power consumption. This ensures longer battery life and enhanced energy efficiency.

Modular design

Employing a modular design can help sensors achieve low power consumption by enabling selective activation, efficient integration, dynamic adaptation, and targeted power management. This approach simplifies component upgrades and maintenance, minimizes complexity, improves isolation, and allows for precise control of power supplies. The result is an energy-efficient, scalable, and flexible sensor system optimized for low-power operation.

Thermal management

Efficient thermal management in sensor design is critical for minimizing power consumption and optimizing performance. Key benefits include:

- We are reducing energy waste and maintaining optimal operational temperatures by preventing overheating.

- Ensuring sensors operate efficiently without excessive power usage.

- We are enhancing reliability by stabilizing performance and preventing thermal drift, which could affect accuracy and necessitate recalibration.

- Extending sensor lifespan by maintaining optimal temperature ranges and reducing power consumption associated with frequent replacements.

- Lowering the need for active cooling systems like fans, thus decreasing overall energy use in the sensor system.

- Preserving sensitivity and accuracy by stabilizing thermal conditions, minimizing the need for power-intensive compensations or recalibrations.

Effective enclosure design and heat sink integration further contribute to energy efficiency by stabilizing internal temperatures and dissipating excess heat, thereby reducing thermal stress and overall power consumption in sensor operations.

Sensor hub, use case example, based on i.MX 8ULP applications processors

Ultra-low power management subsystem: Supports long battery life with efficient power processing.

Sensor hub: Demonstrates deep sleep and wake-up transitions with minimal power consumption.

Evaluation kit for power measurement: Includes tools for power analysis with both GUI and command-line interfaces.

Figure 2: A system comprising of i.MX 8ULP, display and sensor hub (Source)

The i.MX 8ULP features an Energy Flex architecture, which includes the Application, Flex, and Real-Time domains. Its specialized power management system supports various power modes to optimize power consumption, as shown in Figure 3.

Figure 3: Application, flex, and real-time domains in i.MX8ULP architecture (Source)

In the Sensor Hub use case, the system conserves the power state by shutting down the Application and Flex domains while maintaining only the Real-Time domain active. Upon boot-up, the Linux-based Application core (A-core) enters a suspended state, and the M33 microcontroller core (M-core) goes into deep sleep mode, turning off the screen.

When the board is tilted to simulate a wrist lift, the gyroscope sensor (LSM6DSO) detects the motion and sends an interrupt signal to the M33. This triggers the M33 to wake up, read the sensor data, and display the information on the screen. After showing the data for 3 seconds, the system returns to the deep sleep mode, conserving power until the next activity detection.

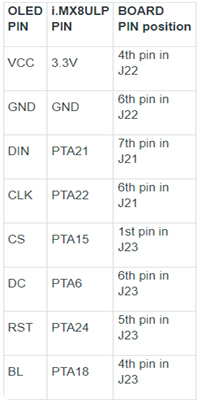

To set up and run the Sensor Hub demo using the i.MX8ULP EVK board, you'll need the EVK board, a WaveShare 1.28-inch LCD module, and the onboard sensors LSM6DSO and MPL3115. The software required includes an M33 image built from the provided GitHub repository: i.MX8ULP CM33 use case. For hardware modifications, solder pins are placed on connectors J23 and J26 on the back of the board, leaving longer pins in front and J21 on the back. Remove resistors R161 and R167 and place a 0-ohm resistor (or short-circuit) at R160 and R166. The panel also requires specific pin mappings for the OLED, connecting VCC, GND, DIN, CLK, CS, DC, RST, and BL to corresponding i.MX8ULP and board pin positions are detailed in Table 1. To run the demo, power on the board, boot Linux, and set it to suspend mode with the command echo mem > /sys/power/state on the A35 console. Start the Sensor Hub application by pressing any key on the M33 console, putting the system into deep sleep mode. The system will wake up upon detecting a tilt or lift of the board, reading sensor data and displaying it on the screen. After displaying data for 3 seconds, it returns to deep sleep.

The Sensor Hub demo with the i.MX8ULP EVK board highlights its high performance and ultra-low power consumption, achieving around 1.1mW in standby with rapid wake-up capabilities. The demo effectively demonstrates peripheral integration, utilizing onboard sensors and an OLED display to show sensor data upon detecting movement. It emphasizes the board's ability to operate efficiently in deep sleep mode and wake up quickly to display real-time data.

Table 1: Pin Mapping

Farnell has partnered with many different suppliers catering to a wide range of sensors and Evaluation kits,

Buy Solution KitsBuy IC Sensors

Conclusion

Achieving low power consumption in sensor design requires a comprehensive approach that integrates various techniques and considerations. Significant energy savings can be realized by selecting appropriate sensors tailored to specific application needs, implementing efficient power management strategies like duty cycling and adaptive sampling rates, and leveraging on-sensor processing and integrated MCUs. Efficient data processing techniques, power-efficient communication protocols, and minimizing leakage currents further reduce power demands. Modular design enhances flexibility and scalability while optimizing power usage through selective activation and targeted power management. Effective thermal management plays a crucial role by preventing overheating, stabilizing performance, and extending sensor lifespan, thus minimizing energy waste. Together, these strategies ensure enhanced energy efficiency, longer battery life, and reliable performance across diverse sensor applications, from wearable devices to IoT systems and beyond.