Adding that last mile connectivity for SMART infrastructure

As the world becomes an ever smarter space, the burden on limited energy resources is bound to grow heavier. By 2050 the world’s energy demand is expected to double from 575 PJ (Petajoules) in 2020 to 1,178 PJ in 2050.

Due to such growth in demand, it is predicted that there will be a 9-fold increase in demand for renewables and a 200% improvement in efficiency . As circa 50% of energy consumed is in ‘Industrials’ including commercial buildings , the future requires the re-engineering of systems to meet this need for efficiency.

Creating new smart factories and buildings in greenfield locations is relatively straightforward if expensive, but we cannot afford to reinvent the wheel for each and every project. In order to make maximum use of the world’s limited resources, especially in densely populated urban environments it will be necessary to upgrade existing buildings, retrofit factory equipment and convert brownfield sites as the transition to smart cities gathers pace.

Improving efficiency and upgrading existing equipment and buildings typically comes down to how to gain access to and leverage data. Helping people to solve problems is all about providing them with data and information about the processes that are of interest to them.

Existing solutions have been built to be reliable rather than flexible, fortunately though the Arduino Pro platform provides effortless integration. Arduino products and services are designed to play nice with third-party solutions, integrating into existing infrastructures or with other brands’ components easily. The entire Arduino ecosystem is agnostic and open-source at heart, allowing industrial customers to add that last-mile connectivity without needing to touch their existing solutions.

Arduino solutions can function outside of a customer’s legacy core operation in a collaborative way, meaning that there is no need to re-audit the line. So factories of the future can save through retrofitting, using what they already have and working faster. Arduino can bring the SMARTS to those ‘oldies but goodies’, the legacy machines that are the cornerstone of manufacturing plants around the globe.

What is overall equipment effectiveness (OEE)?

OEE is a “best practices” metric that identifies the percentage of planned production time that is truly productive. An OEE score of 100% represents perfect production: manufacturing only good parts, as fast as possible, with no downtime.

In reality though, manufacturing industries often experience inefficiencies in their production line, resulting in frequent downtime and reduced overall productivity. They lack real-time visibility into machine performance and struggle to identify the root causes of these issues.

There are five main challenges to implementing OEE:

- Lack of Data Visibility: The existing setup for machines / lines / stations lacks real-time data monitoring capabilities, making it difficult to track machine performance metrics accurately.

- Manual Data Processing: Companies may rely on manual data entry and analysis, which is time-consuming and prone to errors. This hampers their ability to identify and address production inefficiencies promptly.

- Limited Scalability: The current infrastructure does not scale well with the growing volume of data generated by machines, hindering future expansion plans.

- Technical Depth / Interoperability: Some companies might have different types of OT technologies in their sites, making it difficult and/or costly to implement an OEE solution.

- Lack of Skilled Technical Workforce: Implementing an OEE solution might require some level of technical expertise. This is especially hard to acquire with closed-source technology and/or technology not well known by the community, either for end customers or technology suppliers (system integrators).

So, what is the solution?

Optimotion, an official Systems Integrator partner of Arduino, developed the following solution based upon the Arduino Pro platform. The proposed solution leverages IoT technologies, cloud computing, and data analytics to address these challenges effectively:

- Arduino Opta Integration: Implement Arduino Opta micro PLCs to collect real-time data from machines on the shop floor. These are cost-effective and can be easily integrated with existing machinery.

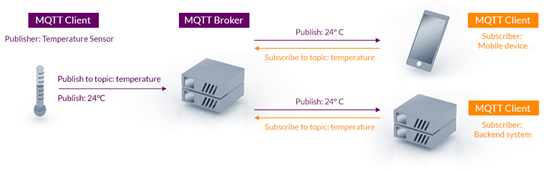

- MQTT Communication with AWS Cloud: Utilize MQTT protocol for lightweight and efficient communication between Arduino Opta micro PLCs and the AWS Cloud instance. This ensures seamless transmission of data to the cloud in real time. The broker could be any of your choices. Main industrial options: Cirrus link, HiveMQ.

- AWS Cloud Architecture: Set up an AWS Cloud instance comprising a MySQL database and Node-RED instance. The MySQL database stores the incoming data, while Node-RED processes the data, calculates OEE, and inserts it into the database.

- Ignition Visualization: Deploy Ignition on premise to connect to the MySQL database hosted on AWS. Ignition provides intuitive dashboards and reports for real-time visualization of OEE metrics, enabling operators to monitor machine performance effectively.

Also, via its store procedures module, the DB manipulation can be easily achieved. Ignition, with its cirrus link MQTT connectors, can become an MQTT subscriber, acquire information in UDT structure via sparkplug B specification and then perform transaction groups for easy UDT-to-DB applications.

Hardware architecture

The Arduino Opta is used as a data concentrator thanks to its powerful Portenta H7 2-core processor. It gathers data using Modbus TCP and RTU, and it is also programmed to be an MQTT gateway to the broker.

In this example, the broker lives in an AWS, but it can also be any kind of broker.

Node-RED would be the “productivity engine” which basically subscribes to the MQTT OEE topics and transforms data into useful OEE historic data.

Also, Node-RED analyzes big chunks of data, and publishes information models through MQTT.

Ignition subscribes to those topics and performs the visualization engine for the OEE application.

Retrofitting to improve productivity through data-driven business decisions

Steelcase, a global home and office furnishings design company, were developing and deploying the Industrial Internet of Things (IIoT) in all 13 of their production plants to improve productivity by shifting to data-driven business operations.

They improved their workflow by building a simple and cost-effective application around the Arduino Opta. When a machine seems to not work properly at random, “Traditionally, you’d get a person out there with a stopwatch and a clipboard, but it could be days or weeks before they might see this issue arise,” says Steven Jones (Technical Process Consultant at Steelcase). Wiring Arduino’s secure and easy-to-use Opta micro PLC (supporting Arduino programming experience and PLC standard languages) into existing equipment allowed Steelcase to monitor signals that indicate when a specific problem was occurring.

“I started working in factories in pre-internet times; the technology now is available to do things that were never imaginable before,” says Jones. “Opta has digital inputs and digital outputs, analog inputs, outputs, everything that a regular PLC would have.”

Unlocking the power of data takes leading enterprises from IoT to AI-powered manufacturing. Industry 4.0 essentially requires embedded systems that connect to the internet, use big data, and finally support decisions about what needs to be done in the factory to achieve better efficiency and productivity: “When you have an idea or an opinion and you can support it with data, you can usually get things to happen much quicker,” Jones observes. At Steelcase, this will naturally lead to increased use of AI: “We’re positioning ourselves also for the time when machines make decisions. I think if we curate our data appropriately and ask the right questions, it could be revolutionary for us.”

Transforming contaminated sites into safe spaces

Converting brownfield sites into habitable residential or office spaces is another challenge where a ‘smart’ approach is aiding the conversion and reducing the risk for occupants. A foundational challenge to buildings constructed over contaminated soil or groundwater from previous industrial usage is ensuring that the indoor air will be safe.

Indeed, where a building rises on top of a site previously contaminated by petroleum or chlorinated solvent products, the off gasses are capped in the ground by the building slab but the gasses can still seep up into the building air. Thus, vapor mitigation systems are used to create a negative pressure under the slab through vent risers and fans which route those gasses safely above the building. Traditionally, environmental consultants would then need to visit their client sites in-person to manually collect differential pressure data to ensure the system was functioning correctly. Beyond the immense time and costs involved with this cumbersome requirement, the potential for a failure to occur to the sub-slab depressurization system between the duration of collecting differential pressure data without any alerts could put building occupants’ health and safety at risk.

AMB Vapor Monitoring provides its customers with 24/7 cloud-based monitoring, control and reporting for their sub-slab depressurization systems utilizing the Arduino Opta and Arduino Cloud. They recognized that they needed a revolutionary solution, one that could efficiently collect and record data from a centralized network of 20 to 200+ subsurface differential pressure testing locations along with providing real-time failure alerts.

Their system consists of a series of tubes running beneath the building slab to various pressure test locations. These tubes are connected to solenoids which in turn are connected to manifolds, which are then routed to the pressure sensor which takes the readings. The reading then goes to the Opta, which transfers the data to Arduino Cloud where it is logged and accessible online. The Modbus reading is recording exactly what the sensor detects within milliseconds, working from very small ranges of accuracy to hundreds of thousand of decimal places. With Arduino Cloud logging and displaying the recordings, AMB Vapor Monitoring can easily view graphs with all the differential pressure data either live, hourly, daily, weekly etc.

As well as transferring the data to the cloud, the Opta also controls a set of relays, switching them on and off. This turns each solenoid on and off to cycle through each pressure test location, measuring and logging the reading back to the cloud.

The system provides customers with peace of mind, as it automatically takes samples every single day for every corner of the building, showing that everything is working correctly and ok for human health.

More about Arduino Opta

The robust and reliable Arduino Opta micro PLC makes industrial and building automation accessible to everyone. Its versatility allows for integration with existing machines, devices, and production lines, as well as with any of the elements in the modular Arduino ecosystem – from compact sensor modules to powerful SOMs and gateways – offering customizable end-to-end solutions for diverse applications.

Designed for security and durability, Opta supports OTA firmware updates and ensures data security from hardware to the cloud through its onboard secure element and compliance with the X.509 Standard.

Opta enhances industrial automation capabilities by integrating seamlessly with load cells or vision systems to optimize manufacturing processes. It facilitates tasks such as managing production flow on conveyor belts, synchronized time printing on labels using Network Time Protocol (NTP), and real-time monitoring via local HMIs, Bluetooth® Low Energy, or remote connection to Arduino Cloud with custom dashboards. Additionally, Opta enables predictive maintenance by leveraging its computational power and machine learning algorithms to detect and preemptively address anomalies, ensuring uninterrupted operations.

Conclusion

Enhance your smart infrastructure with Arduino’s Opta Micro PLC, designed to provide that crucial last-mile connectivity. For comprehensive product insights click here

Download article in PDF