A guide to IoT field device design

Internet of Things (IoT) structures gather, cross-reference and analyse data from large numbers of remote or widely-dispersed edge sensors, or nodes that are deeply embedded within the processes that interest us. This calls for sensor devices that are small, low-cost, highly reliable, robust and mostly if not entirely maintenance-free. Achieving these objectives depends partly on the sensor device design, but also on how the data processing task is divided up between the sensor node and the gateway that communicates with the Internet.

Although edge sensing usually comprises temperature sensors, pushbuttons or other simple devices as described above, complex, high-data components such as smartphones, cameras, or personal assistants like Amazon’s Alexa/Echo units may also be included. Additionally, the edge includes actuators as well as sensors.

Currently, the gateway function is often fulfilled by two components; a hub, which handles a range of data formats for different edge device types, and a router which handles Internet communications. In the future, the router and hub will increasingly be integrated into a single gateway unit.

Collectively, the edge components’ prime responsibility is to facilitate the transfer of data between edge sensor and actuator devices, and the Internet. However the edge is often also designed to act intelligently on the data that it handles. This is to reduce the load on the central cloud resource, and to provide some local autonomy. How the intelligence and processing load is distributed between the edge devices and gateway depends on the requirements of each application.

Below, we look at some generic considerations for edge devices and gateways, and then review a range of real-world market areas – consumer, automotive, medical and industrial – to see how edge solutions are being adapted and implemented in these various situations.

Edge devices – sensors

Edge devices are either highly-functional, like smartphones, or simple, like temperature sensors, as described above. Each device comprises at least the sensor or actuator, a processor, a communications port and a power supply. Apart from any IoT connectivity considerations, devices must be reliable and physically suited to their target environment. They need protection from temperature extremes, shock and vibration, threat of liquid or material ingress and vandalism. They must also meet any applicable size and cost application constraints, especially if an application calls for large numbers of sensors.

Power management is essential. Nodes that are in remote locations, or deeply embedded in equipment, must have low or zero maintenance requirements. Battery replacement intervals should be extended to years, or ideally eliminated entirely using energy harvesting.

For example, if the sensor does not need to transmit data continuously, the processor should go into a minimum-power sleep mode, waking only to process bursts of data from the sensor when necessary. The communications protocol should be carefully selected; the ideal is one with sufficient data bandwidth and transmission distance for the application, but without excessive performance or power consumption.

Fig.1: EnOcean solar-powered wireless temperature sensor

Another reality of edge design is that a new product may have to fit in with an existing infrastructure. There may be a de facto gateway or hub, or an established wireless protocol standard. Alternatively, some applications may use a cabled network such as Profibus or CAN Bus.

Gateways

Gateways, as discussed here, combine hub and router functions, where hubs communicate with edge devices and routers talk to the Internet.

In this role, gateways consolidate data from disparate sources that use different protocols and bridge them to the internet. This relieves individual nodes from the cost, complexity and power needs of a direct high-speed internet interface.

At their simplest, gateway devices exchange edge data with the Internet, and handle any data packing and unpacking functions. They can handle many protocols, for example ZigBee, Bluetooth or 6LoWPAN. They can also manage devices that use IP protocols natively. More complex gateways can process sensor data; evaluation, filtering, and high-level management tasks such as generating an alarm if a critical threshold is exceeded. Nodes can leverage this gateway capability, so each node in an array is simpler, lower cost and less power-demanding.

Some gateways have a further level of intelligence, and can solve interoperability issues between complex connected devices. However, although some are widely interoperable, others, like Apple Bluetooth devices, only communicate with one another.

An intelligent gateway may also support a web-based user interface, accessible through a PC, tablet or smartphone, that allows users to view and control connected devices. The gateway becomes an autonomous local controller in complement to the remote, cloud-based processing service.

Security is essential. As the levels of automation and connectivity in our homes, workplaces, infrastructures and even bodies increase, so does the corresponding threat of cybercrime. To combat this, gateways with increased intelligence provide better opportunities to build in security measures. These include secure booting and anti-tamper firmware, authentication and authorisation strategies, certificate and key management, embedded firewalls for intrusion detection and prevention, and encrypting data in transit. Other security strategies include event recording, system auditing and reporting, and device policy management tools and procedures.

Hub and gateway devices tend to use relatively powerful processors such as the ARM A8 or A9. Single board computers are typically used for low production volumes, up to around 500 units. Beyond this, it becomes economical to customise the SBC, or develop a fully-custom board. Engineers can start investigating gateway requirements and possibilities by working with one of the many available IoT gateway reference design kits.

Field devices in the real world

Above, we have explored the generic considerations that apply to all field devices. Now we look at some real-world areas – consumer, automotive, medical and industrial – and see how field devices are being adapted for these widely-varying applications.

Consumer

Domestic installations typically use a router or gateway that handles Internet communications, and has Wi-Fi and/or Ethernet connections. Communications with smartphones, cameras or personal assistants such as Amazon’s Alexa, using Wi-Fi, will be relatively easy, but such routers will not be able to communicate directly with process I/O type edge devices that use lower power networks.

However, solutions exist in the form of home hubs like the Wink Hub 2 . Wink works with devices that use Z-wave, ZigBee, Lutron Clear Connect, Kidde, Bluetooth and Wi-Fi. This gives access to thermostats, security cameras, door locks, lighting systems, sensors, ceiling fans, garage door openers, window blinds, doorbells, and more, with typically 40 – 50 edge nodes found within an individual home. Wink also works with Amazon's Alexa voice commands and has its own If This Then That (IFTTT) channel.

The hub has Secure Boot, a hardware-based security feature that ensures only Wink software can run, making it difficult for hackers to compromise smart home devices.

Future smart home scenarios are expected to become more user-friendly and elegant than those typically found today, as hubs and routers become increasingly integrated into single gateway units.

Field devices found within domestic environments are unlikely to be subjected to extreme temperatures or other ambient challenges, and very high accuracy or low calibration drift are rarely required. However, they must withstand high numbers of on/off cycles, and be rugged enough for careless, ignorant handling. They must also be resilient to data corruption.

Unlike other applications, the home environment provides freely available power to those devices that can use it. Different wireless protocols handle different device types. Wi-Fi is popular for cameras, smartphones or personal assistants such as Amazon’s Alexa, with large-volume data output. These communicate directly with routers. ZigBee is used for devices like light sensors or switches, with low data volumes. Bluetooth is also used by many devices.

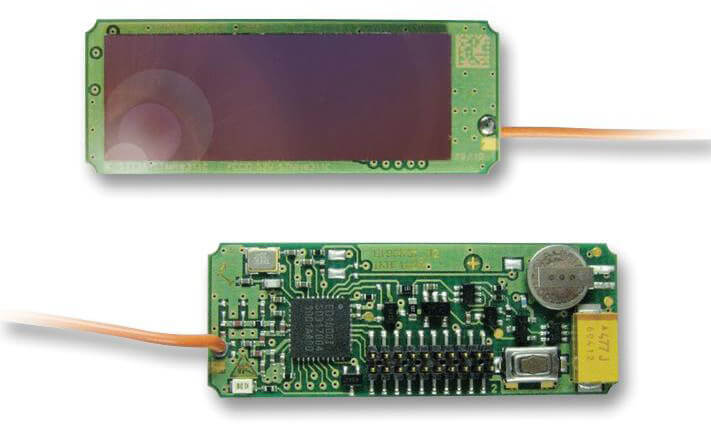

Wearable devices

Wearable devices, like home automation, have a direct impact on consumers. These are now being used for convenience and information, and for healthcare and wellbeing. Within the home, they could interact with other smart devices, for example to set your preferred lighting level when you watch TV. Wearable devices that take biometric readings can warn you of the possible onset of a fever, or provide data for your doctor to analyse.

Fig.2: Wearable devices that take biometric readings can provide data for your doctor to analyse – Image via Pixabay

Nymi is a wearable device that integrates biometrics with security. As a bracelet, it recognises ECG patterns – which, like fingerprints, are unique to individuals – and uses them for authentication, as a replacement for passwords and PIN numbers. The Nymi also supports simple, task-specific gesture commands using both motion sensors and proximity detection.

Automotive

The IoT offers the potential – and in many instances the reality – of addressing many issues relating to vehicles and traffic. In fact, these issues affect almost anyone in any city or urban neighbourhood. Traffic congestion and parking difficulties lead to lost productivity and frustration for car drivers, while pollution from heavy traffic is a serious health risk for anyone living or working in the area.

Area traffic managers must optimise traffic flows to provide a better environment for their citizens, protect health, and comply with pollution legislation. Fleet managers, whether for public transportation or goods vehicles, can use the IoT’s information and intelligence capabilities for optimising vehicle and driver performance; improving both safety and productivity.

If reducing traffic congestion is a priority, then parking solutions make a good place to start. Drivers searching for parking places contribute significantly to congestion. In one study , such drivers in Freiburg, Germany reached a record level of 74% of all traffic.

One IoT-based response comes from the City of Westminster, a central London borough with extremely heavy traffic and high parking bay occupancy. Phase one of their project involved installing SmartEye battery-powered wireless infrared sensors into 3,000 of the borough’s 12,000 parking bays. These communicate with nearby wireless receivers mounted on streetlamps using a proprietary communications protocol. These receivers in turn communicate via a wireless ZigBee mesh network to a master SmartLink controller, then on to a central reporting system over a 3G mobile data network. Drivers find available spaces using an associated app.

The Council is currently evaluating phase one, but expects the project to pay for itself within three years. They use open applications programming interfaces (APIs) to allow other London boroughs to implement their own smart parking solutions to work with the Westminster system; in time, London could be entirely covered by a single smart parking app. Additionally, independent innovators can develop their own smartphone apps that use the Westminster data. Cities of Reading and Coventry already followed the Westminster example and installed around 700 Nwave's wireless vehicle detection sensors that use magnetometers alongside infrared sensing for improved accuracy.

Streetlights are now improving road conditions, in an ambitious ‘Smart Cities’ program launched by AT&T at CES 2017 in Las Vegas. The telecom has signed a deal with GE to install its Current CityIQ sensors into streetlights in various cities and municipalities around the US, starting with San Diego. The aim is to not just provide more intelligent lighting, but also monitor things like traffic circulation, parking spots, air quality, weather emergencies and even gunshots.

The 14,000 LED fixtures will reduce city energy costs by up to $2.4 million, and the 3,200 "CityIQ" sensor nodes with cameras, microphones and other sensors will add IoT connectivity. AT&T will act as the data carrier "and provide highly secure connectivity" for the San Diego deployment, according to a press release.

IoT sensors are also finding ever-more applications in cars and other vehicles, promoting the concept of the connected car. As well as navigation, parking and infotainment systems, vehicles use process-oriented sensors to improve performance and safety; good examples are devices based on SAW (Surface Acoustic Wave) technology. These measure pressure, temperature and torque by detecting strain changes. Transense Technologies , manufacturers of these devices, apply them to three areas within the vehicle – TPMS (Tyre Pressure Management System), EPAS (Electronic Power Assisted Steering) and Powertrain. Additionally, connected cars can facilitate the eventual launch of self-driving cars , providing robust support for the vehicle-to-vehicle and vehicle-to-infrastructure communications technology needed to see self-driving cars become a reality.

Medical

IOT technology can improve medical outcomes in both hospital and remote locations. In hospitals, sensors collect comprehensive physiological data and use gateways or cloud computing to analyse and store the information, then send the analysed data wirelessly to caregivers for further analysis and review. This simultaneously improves the quality of care through automation and constant attention, and lowers costs by eliminating the need for a caregiver to actively engage in data collection and analysis.

Meanwhile, small, powerful wireless solutions connected through the IoT are now allowing monitoring to come to remotely-located patients at home. These solutions can be used to securely capture patient health data from a variety of sensors, apply complex algorithms to analyse the data and then share it wirelessly with medical professionals who can make appropriate health recommendations.

Medical instrumentation used in these applications is subject to some constraints. Sensors must offer high accuracy, which does not degrade over time; stability for typically three years at least is essential. This can be a challenge due to the low values of measured variables (microvolts, low frequencies) compared to other industries.

Hygienic design is also important for instrumentation that is inserted into or touches a patient’s body. Additionally, both patients and doctors must be protected from the risk of electric shock from medical instrumentation. In the EU market, this is covered by CE compliance; this uses the concept of MOOP (Means of Operator Protection) and MOPP (Means of Patient Protection). These set out levels of isolation, creepage clearance and insulation requirements that will provide the protection levels needed.

Industry

We have already discussed the role of small, robust, low cost sensors within the IoT environment – and they have a special importance for the production and manufacturing industries. Embedding them into factory floor machines and systems offers operators several major benefits. These relate to improving availability and reducing downtime, reducing energy losses and costs, preventing loss of production stock, and improving product quality and consistency.

Fathym , a company that provides end-to-end solutions for the Industrial Internet of Things, has defined some major benefits of the IoT for manufacturing industries. The first is about how more granular information can facilitate greater energy efficiency. Many companies obtain energy consumption data only from utility bills or energy monitoring tools, which both have limited points of data; they don’t provide any clue about opportunities to reduce energy consumption.

By deploying IOT sensors throughout a factory’s production line equipment, managers can spot which machines are underperforming and wasting energy, so they can take corrective action as appropriate.

Machine sensors are also contributing to predictive maintenance and significant reductions in plant failures. For example, if a sensor indicates that the temperature within a critical machine is starting to increase, staff can be alerted and corrective action taken before the situation develops into a machine failure.

Preventing machine failure also forestalls consequential losses, such as loss of production time or irreparable damage to feedstock inside a machine at time of failure.

Improving product quality is a primary goal for manufacturers, as it not only enhances reputation but also reduces waste, lowers costs, increases customer satisfaction and improves sales. However, product quality can be compromised by equipment faults such as incorrect settings, calibration drift or poor maintenance. Quality problems caused by such issues may not reveal themselves for many months, when large product quantities have been shipped; leading to major recall costs and reputation damage.

Such problems can be prevented by using IoT sensors to flag these otherwise hidden problems, so repairs can be made and faulty products isolated before reaching the marketplace.

Overall, IoT technology is allowing plant managers to become proactive rather than reactive, with higher visibility of their entire process. They can make faster and more informed decisions at the precise moment of relevance.

Fig.3: Industrial manufacturing process – Image via Wikimedia

Conclusion

The IoT is allowing us previously unattainable insights and control of the processes that affect us, from infrastructure schemes to home automation and even our bodies. Sensors and edge devices play a critical role in the IoT landscape, because as they become smaller, lower-cost, more rugged and reliable, they can be deployed in large quantities into previously unsustainable situations. Their new, rich data streams are informing the powerful, cloud-based computing resources that ultimately provide the IoT’s elevated level of visibility.

While providing benefits today, IoT installations are providing a platform for the future. Connected cars could become driverless cars, for example, or smart homes could become fully integrated into smart cities. Corporate directors in central office will have granular access to processes across their widely-dispersed enterprise locations.

Naturally, there are barriers to be overcome. Although standardisation work is being done for various parts of the IoT chain, the IoT is not a single entity to which an overall standard can be applied. Also, the more we become connected, the greater the need for robust security.

Nevertheless, the increasingly visible rewards of the IoT mean that enterprises will continue to invest in the technology and seek their own solutions. A survey of nearly 1,000 enterprises worldwide conducted by 451 Research from August to October 2016 shows that 71% of organizations are gathering data as part of IoT initiatives today. They expect to increase their IoT technology spending by 33% over the next 12 months, the study says.

References

https://www.element14.com/community/docs/DOC-75645/l/iot-gateway-reference-design

http://uk.pcmag.com/wink-hub-2/84889/review/wink-hub-2

http://uk.pcmag.com/ifttt/14436/review/ifttt

“Aparkalypse Now”, The Economist, April 8th – 14th 2017

https://iotuk.org.uk/smart-parking

https://www.smartparking.com/technologies/in-ground-vehicle-detection-sensors

https://www.engadget.com/2017/02/27/atandts-smart-streetlights-can-smooth-traffic-detect-gunshots

https://eboertjes.wordpress.com/2017/05/18/the-rise-of-the-connected-car-betanews

https://fathym.com/2017/05/5-powerful-benefits-iot-manufacturing-industry

A guide to IoT field device design. Date published: 14th June 2017 by Farnell